Orders & Worldwide

Orders & Worldwide

Intro

Are you curious about the structure and components of industrial robots? Then you've come to the right place! In this blog post, we'll be taking a closer look at the anatomy of an industrial robot. We'll explore the various components that make up an industrial robot, discuss the different types of robots and their capabilities, and uncover the potential applications of these machines.

From large-scale production lines to hazardous environments, we'll find out how industrial robots are transforming the way we work. So join us on this exciting journey as we explore the structure and components of industrial robots.

Industrial robots are complex machines that are revolutionizing various industries. Understanding industrial robots is crucial in order to appreciate their capabilities and the impact they have on our lives. These robots are designed to perform tasks that were traditionally carried out by humans, with the aim of improving efficiency, accuracy, and safety in a wide range of applications.

Industrial robots can be found in industries such as manufacturing, automotive, aerospace, healthcare, and more. They are programmed to carry out repetitive tasks with precision, speed, and consistency. These tasks can include welding, painting, assembly, material handling, and quality control, among others.

What sets industrial robots apart from other types of robots is their ability to work in challenging environments. They are designed to withstand high temperatures, hazardous materials, and even work in confined spaces. This makes them versatile and suitable for a wide range of applications.

To understand industrial robots better, it's essential to delve into their anatomy and major components. From the robot arm to the end effector, each part plays a crucial role in enabling the robot to perform its tasks effectively. The control system is another integral component that determines the robot's movements and actions.

Overall, understanding industrial robots allows us to appreciate their capabilities and the positive impact they have on industries worldwide. From improving productivity to ensuring worker safety, these machines are transforming the way we work and paving the way for a more efficient and technologically advanced future.

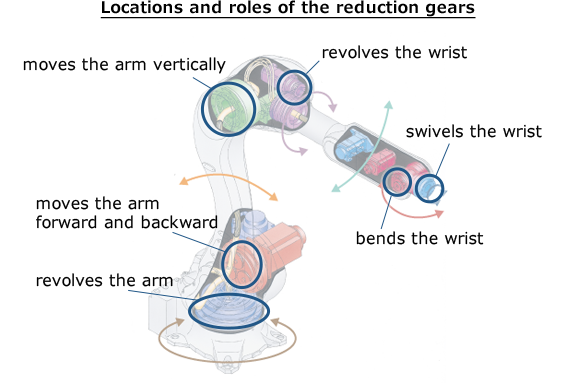

Now, let's delve into the fascinating world of the anatomy of an industrial robot. The structure of an industrial robot is designed to mimic the movements of a human arm, with various components working together seamlessly to perform a wide range of tasks.

At the core of the robot is the robot arm, which is composed of several segments called links, connected by joints. These joints allow the arm to move in multiple directions, enabling the robot to reach different positions and angles.

At the end of the robot arm is the end effector, which is the part that interacts with the work piece or the environment. The end effector can be a gripper, a welding tool, a paint sprayer, or any other tool depending on the task at hand. It is designed to securely hold or manipulate objects with precision.

Supporting the robot arm and end effector is the base of the robot, which provides stability and houses the necessary electronics, motors, and sensors. The motors and sensors are responsible for the robot's movements and feedback, ensuring accurate positioning and control.

The control system acts as the brain of the robot, receiving instructions and translating them into actions. It determines the sequence of movements, speed, and force required for the robot to carry out its tasks. The control system is programmed using sophisticated software, allowing for customization and adaptability.

Now, let's take a closer look at the major components that make up an industrial robot. These components work together seamlessly to ensure the robot's functionality and effectiveness in performing tasks.

One of the key components of an industrial robot is the robot arm. The robot arm consists of several segments called links, which are connected by joints. These joints allow the arm to move in multiple directions, enabling the robot to reach different positions and angles. The robot arm is responsible for carrying out the physical tasks, such as welding or assembly.

Another important component is the end effector. The end effector is the part of the robot that interacts with the work piece or the environment. It can be a gripper, a welding tool, a paint sprayer, or any other tool depending on the specific task. The end effector is designed to securely hold or manipulate objects with precision.

Supporting the robot arm and end effector is the base of the robot. The base provides stability and houses the necessary electronics, motors, and sensors. These components are responsible for the robot's movements and feedback, ensuring accurate positioning and control.

Finally, we have the control system, which acts as the brain of the robot. The control system receives instructions and translates them into actions. It determines the sequence of movements, speed, and force required for the robot to carry out its tasks. The control system is programmed using sophisticated software, allowing for customization and adaptability.

In summary, the major components of an industrial robot include the robot arm, the end effector, the base, and the control system. These components work together to enable the robot to perform tasks with precision, accuracy, and efficiency.

Now let's delve into the fascinating world of the control system of industrial robots. The control system is the brain of the robot, responsible for translating instructions into actions. It determines the sequence of movements, speed, and force required for the robot to carry out its tasks with precision and accuracy.

The control system of an industrial robot is programmed using sophisticated software, allowing for customization and adaptability. This means that the robot can be programmed to perform a wide range of tasks and adjust its movements based on the specific requirements of each task.

The control system receives instructions from an operator or a central computer, and then coordinates the movements of the various components of the robot, such as the robot arm and the end effector. It ensures that the robot moves in the correct sequence and at the right speed to perform its tasks efficiently.

Additionally, the control system also incorporates sensors that provide feedback to the robot. These sensors allow the robot to detect changes in its environment and make adjustments to its movements if necessary. This feedback loop ensures that the robot can operate with precision and adapt to any changes or variations in the work environment.

Overall, the control system is an integral part of an industrial robot, enabling it to carry out complex tasks with speed, accuracy, and efficiency. Without the control system, the various components of the robot would not be able to work together seamlessly, and the robot would not be able to perform its tasks effectively.

The control system truly is the brains behind the operation of an industrial robot, making it an essential component in the structure of these incredible machines.

When it comes to industrial robots, the end effector is a crucial component that determines the type of tasks the robot can perform. The end effector is the part of the robot that interacts with the work piece or the environment, and it comes in various forms to suit different applications.

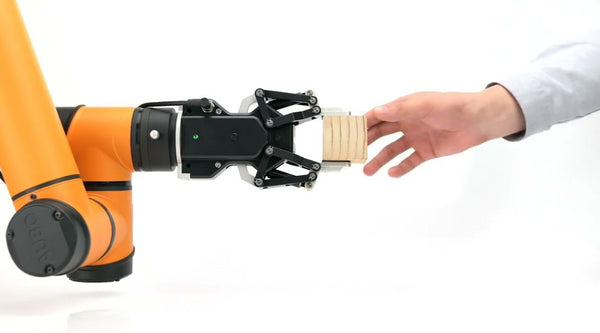

One common type of end effector is a gripper, which is used for tasks such as picking up and placing objects. Grippers can come in different shapes and sizes, with some featuring multiple fingers for more versatile gripping capabilities.

Another type of end effector is a welding tool, which is used in industries such as automotive and manufacturing. These tools allow the robot to perform precise and consistent welding tasks, improving efficiency and quality.

For painting tasks, robots can be equipped with paint sprayers as end effectors. These sprayers ensure an even and smooth application of paint, reducing wastage and ensuring a high-quality finish.

Other types of end effectors include cutting tools, screwdrivers, and suction cups, each designed for specific tasks and industries.

The choice of end effector depends on the specific requirements of the task at hand, as well as the industry and environment in which the robot will be operating. Industrial robots can be easily adapted by changing the end effector, allowing for versatility and flexibility in a wide range of applications.

Whether it's gripping, welding, painting, or any other task, the end effector is the key to the robot's ability to interact with the world and perform its designated function with precision and accuracy.

Industrial robots have a wide range of applications across various industries, revolutionizing the way we work. These machines are designed to perform repetitive tasks with precision and accuracy, improving efficiency and productivity in numerous sectors.

One of the main applications of industrial robots is in manufacturing. They can be found on production lines, performing tasks such as assembly, welding, and material handling. By automating these processes, industrial robots can significantly increase production speed and quality whilst reducing costs.

In the automotive industry, robots play a crucial role in tasks such as painting, welding, and assembly. They can work with precision and consistency, ensuring a high-quality finish and reducing the risk of errors.

Industrial robots are also used in hazardous environments, where it may be dangerous for humans to work.

They can handle tasks such as working with toxic chemicals, extreme temperatures, or confined spaces. By using robots in these environments, companies can ensure worker safety and avoid potential health risks.

Furthermore, industrial robots have applications in healthcare, where they can assist with tasks such as surgery, rehabilitation, and patient care. Robots can perform delicate and precise procedures, reducing the risk of human error and improving patient outcomes.

The potential applications of industrial robots are vast, and as technology continues to advance, we can expect to see them in even more industries.

From agriculture to aerospace, robots are transforming the way we work and opening up new possibilities for increased productivity and efficiency.

As we embrace this technological revolution, it is important to continue exploring the applications of industrial robots and harness their full potential.

The future of industrial robotics is brimming with exciting possibilities. As technology continues to advance at a rapid pace, we can expect to see a number of trends and developments in the field of industrial robotics. One of the key trends is the integration of artificial intelligence (AI) and machine learning into industrial robots.

This will enable robots to become more intelligent and adaptive, allowing them to learn from their experiences and make decisions in real-time. With AI, industrial robots will be able to adapt to changing environments, optimize their movements, and even collaborate with humans more seamlessly.

Another trend we can anticipate is the increased use of collaborative robots, also known as cobots. These robots are designed to work alongside humans, assisting with tasks and enhancing productivity.

Collaborative robots are equipped with sensors and safety features that allow them to operate in close proximity to humans without causing harm. This opens up new possibilities for human-robot collaboration in industries such as manufacturing, healthcare, and logistics.

Additionally, we can expect to see advancements in the field of robotics in terms of mobility. Mobile robots, such as AGVs (Automated Guided Vehicles) and drones, are becoming increasingly prevalent in industries that require transportation and logistics. These robots are capable of autonomously navigating through complex environments, enhancing efficiency and reducing manual labour.

The use of advanced sensing technologies will also play a significant role in the future of industrial robotics. Robots equipped with advanced sensors, such as vision systems and tactile sensors, will be able to perceive and interact with their environment more effectively. This will enable them to carry out tasks with greater accuracy and precision.

Overall, the future of industrial robotics holds immense potential. From the integration of AI and machine learning to the rise of collaborative robots and advanced sensing technologies, we can expect to see robots that are more intelligent, adaptable, and efficient.

These advancements will undoubtedly transform industries and revolutionise the way we work, opening up new possibilities for increased productivity, safety, and efficiency.

0 of 3 items selected

Leave a comment on this topi