Orders & Worldwide

Orders & Worldwide

Selecting the right servo drive for your industrial robot applications is crucial for ensuring optimal performance, precision, and reliability. Here’s a comprehensive guide to help you make an informed decision:

Understanding Servo Drives

Servo drives, also known as servo amplifiers, are electronic devices that control the motion of servomechanisms, such as industrial robots. They receive command signals from a control system and adjust the motor's operation accordingly. Key features include high precision control, rapid response to command signals, efficiency in energy consumption, and robustness in various industrial environments

Key Considerations

Application Requirements: Analyze your robot's motion requirements, including torque, speed, precision, and environmental conditions. This analysis will guide you in selecting a servo drive that meets your performance expectations.

Motor Compatibility: Ensure the servo drive is compatible with the servo motor you intend to use. The motor's specification sheet will provide peak and continuous current requirements, as well as the motor voltage rating.

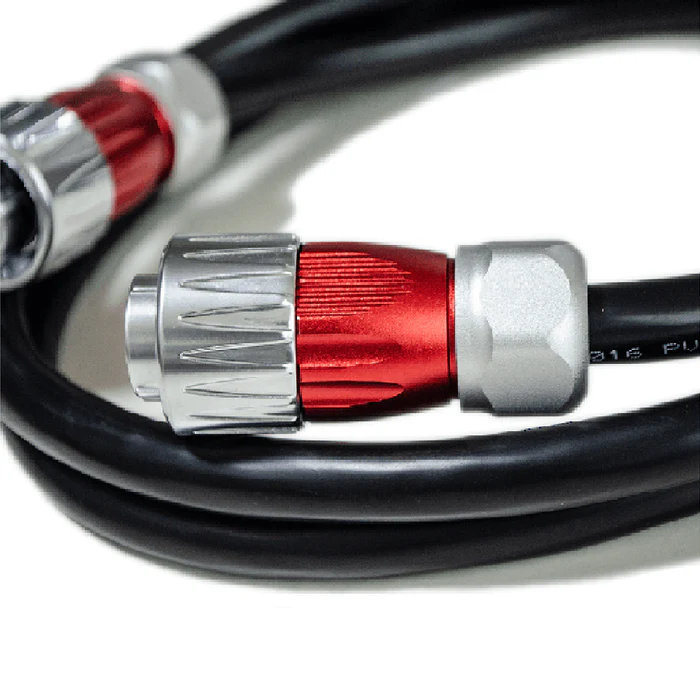

Feedback Systems: Servo drives require accurate feedback for precise control. Encoders are commonly used for this purpose. Choose a servo drive that can interface with the type of encoder used by your motor.

Communication Protocols: For integration into broader automation systems, ensure the servo drive supports the necessary communication protocols, such as EtherCAT or CANopen.

Environmental Factors: Consider the operating environment's temperature, humidity, and potential for vibration. Servo drives should be rated for the environmental conditions they will encounter.

Energy Efficiency: Look for servo drives with features like regenerative braking to improve energy efficiency and reduce operating costs.

Reliability and Support: Choose a servo drive from a reputable manufacturer with a history of reliability and strong technical support.

Types of Servo Drives

AC Servo Drives: Offer high efficiency and power, with better performance at high speeds but require more complex control algorithms.

DC Servo Drives: Provide simpler control mechanisms and high starting torque but are limited by brush wear and maintenance.

Brushless Servo Drives: Require less maintenance, offer high efficiency and performance, and are critical for applications needing force control.

Applications

Servo drives are used in a variety of industrial robot applications, including robotic arm , mobile robots, humanoid robots, exoskeletons, robotic grippers, 3D printing, CNC machining, autonomous vehicles, medical robotics, and educational platforms.

Future-Proofing Your Selection

As technology advances, servo drives are becoming more intelligent and efficient. Consider the potential for future expansions or upgrades when selecting a servo drive. A modular and flexible solution allows for easy integration of additional drives or functionalities as your application requirements evolve.

Conclusion

The selection of the right servo drive is pivotal for the success of your industrial robot applications. By considering the factors mentioned above, you can optimize the performance, precision, and reliability of your robotic systems, ensuring they operate efficiently in the ever-evolving industrial landscape.

{"one"=>"Select 2 or 3 items to compare", "other"=>"{{ count }} of 3 items selected"}

Leave a comment on this topi