Orders & Worldwide

Orders & Worldwide

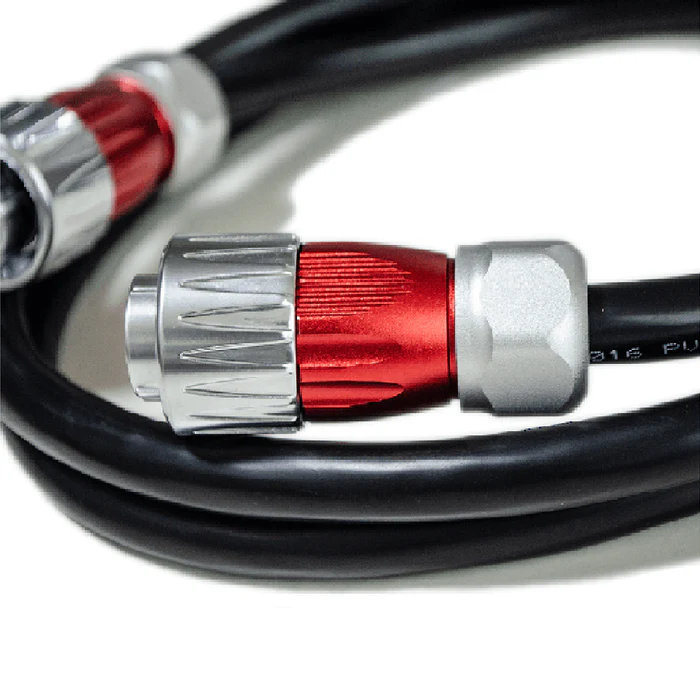

Model: TLC6342F322111

Customer Feedback: "3" flashes internal short circuit

Failure Causes: The current through the large chip caused internal damage, while leading to circuit board damage

Berger Lahr is a German company founded in 1941, initially producing measuring instruments, and later expanded to controllers and relays. In 1972, Berger Lahr developed the world's first five-phase stepper motor and introduced the world's first three-phase stepper motor in 1993. In 2000, Berger Lahr became part of Schneider Electric and was renamed Schneider Electric in 2008. In 2000, Berger Lahr became part of Schneider Electric and was renamed Schneider Electric Motion Deutschland in 2008.

Today, Berger Lahr offers a complete range of motion control products, including servo drives, servo motors, stepper drives, stepper motors and integrated drives. These products are integrated into Schneider Electric's Lexium family for a wide range of machine automation applications.

Berger Lahr Servo Drives are drives for controlling servo motors. They are part of Berger Lahr's Motion Control product family and are now integrated into Schneider Electric's Lexium family. These servo drives are highly flexible and suitable for a wide range of machine automation applications.

Specifically, Berger Lahr servo drives can control synchronous AC servo motors, providing motion control with high accuracy and performance. For example, the TLC6342F322111 uses a three-phase 230/480 volt power input for synchronous AC servo motors, which are widely used in industrial automation, robotics, and CNC machine tools.

However, in the process of using robots, you may encounter servo drive can not start normally, can not be turned on, or start immediately after the shutdown of the situation, to the normal production operation has brought a lot of trouble. This article will focus on common failures and solutions, and the repair and maintenance of the drive to begin to describe.

Failure Cause 1: HALL Sensor Failure

Solution 1: Measure the voltage of HallA, HallB, and HallC when the motor is rotating. The voltage value should be between 5VDC and 0.

Fault Cause 2: HALL phase failure

Solution 2: Check that the motor phase selector switch is set correctly.

Fault Cause: Supply voltage is too low, less than the minimum required voltage.

Solution: Check and increase the power supply voltage.

Cause 1: Wrong position of the deviation potentiometer.

Solution 1: Reset

Fault Cause 2: Test/offsets switch in test position when not used for testing.

Solution 2: Move the test/deviation switch to the deviation position.

Fault Cause 3: The phase of the brushless motor is incorrect.

Solution 3: Test or determine the correct phase.

Cause 1: Motor deviation counter overflow error occurs when a long command pulse is input.

Solution 1:

Fault Cause 2: Motor deviation counter overflow fault occurs during operation

Solution 2:

Cause: The current monitor output is not isolated from the AC power supply (transformer).

Solution: You can use a DC voltmeter to test and observe.

After long-term use, the dust and debris accumulated inside the drive will affect its operation, which in turn will reduce the performance of the equipment. Therefore, regular cleaning of the drive is essential to maintain its stable operation. When cleaning the drive, be careful not to use materials that will damage the surface of the protective coating; it is best to use special cleaning agents.

Electronic devices generate static electricity during operation, and static electricity causes interference to the drive, affecting its normal operation. To prevent static interference, it is recommended to use anti-static mats or wear anti-static clothing.

Prolonged use of the product may cause the drive to overheat and affect its normal operation. To prevent overheating, it is recommended to use a cooling fan or install a heat sink to ensure that the drive can operate within the normal temperature range.

The data in the drive is one of the most important parts of the device, and the loss of data will have a serious impact on the work. Therefore, backing up the data regularly can effectively prevent the damage caused by data loss and protect the data in the drive.

The above methods can effectively maintain and care for the Berger Lahr servo drive, prolong its service life, and ensure the normal operation of the device. When maintaining and caring for the drive, remember to avoid disassembling the drive or modifying the internal components of the drive to avoid irreversible damage.

The article and images are from the internet and are copyrighted by the original authors.

{"one"=>"Selecione 2 ou 3 itens para comparar", "other"=>"{{ count }} de 3 itens selecionados"}

Selecione o primeiro item para comparar

Selecione o segundo item para comparar

Selecione o terceiro item para comparar

Deixe um comentário