Commandes et dans le monde entier

Commandes et dans le monde entier

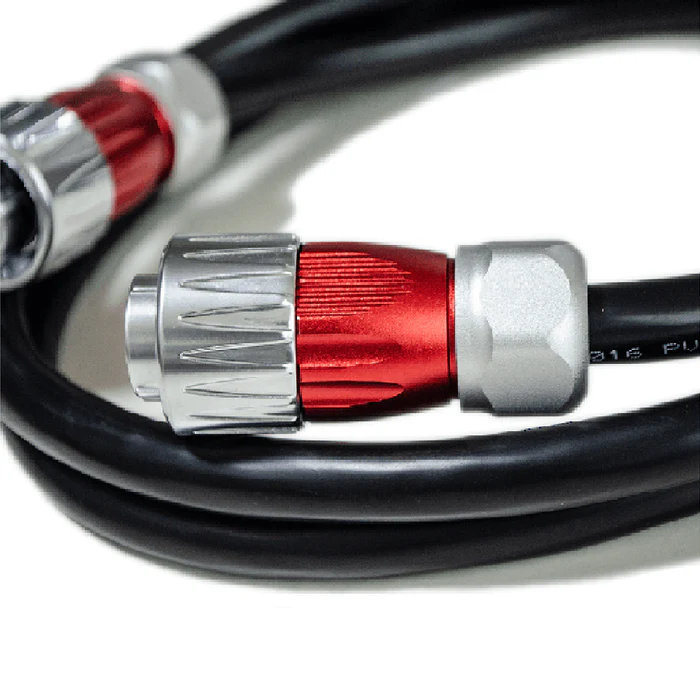

Custom cables are specialized electrical cables designed and manufactured to meet the unique specifications of individual applications. They play a crucial role in various industries, providing tailored solutions where standard off-the-shelf cables do not meet the required criteria. This article delves into the world of custom cables, exploring their importance, the process of customization, and the benefits they offer.

Custom cables are created to fulfill specific electrical or physical requirements that are not covered by standard cables. They are engineered to exact customer specifications, which may include unique conductor sizes, shielding, insulation types, colors, and connector configurations.

Custom cables are designed to meet unique electrical and physical requirements, such as specific voltage or current ratings, resistance to certain chemicals, or the need for extreme flexibility.

They serve a wide range of applications, from industrial machinery and medical equipment to aerospace and military technology, where the demands of the environment or the precision of the task require specialized cables.

Customization allows for the incorporation of advanced materials and construction techniques, leading to enhanced performance, durability, and reliability in demanding conditions.

Designed for the transmission of power, these custom cables may have to withstand high temperatures, handle heavy current loads, or be resistant to oil and chemicals.

Used for the transmission of signals, these cables are tailored for low signal loss and high-speed data transfer, often with specific shielding and insulation to prevent interference.

These cables combine multiple conductors into a single cable, allowing for complex connections with a single, organized cable assembly.

When considering custom cables, the following factors should be taken into account:

Understanding the specific needs of the application, including the environment in which the cable will operate, is crucial for determining the appropriate cable specifications.

The choice of materials for insulation, shielding, and conductors is critical for ensuring the cable's performance, durability, and safety.

Custom cables must comply with relevant industry standards and safety regulations, which may vary depending on the region or industry.

While custom cables can be more expensive due to their specialized nature, they often provide a more cost-effective solution in the long run by meeting specific needs precisely.

Custom cables offer a flexible and efficient solution for applications that require unique electrical or physical properties. By working closely with manufacturers to define the exact specifications, customers can ensure that the custom cables they receive will meet their precise requirements, leading to improved performance and reliability in their systems. As technology continues to evolve, the demand for custom cables is likely to grow, reflecting the increasing need for specialized solutions in various industries.

{"one"=>"Sélectionnez 2 ou 3 articles à comparer", "other"=>"{{ count }} éléments sélectionnés sur 3"}

Sélectionnez le premier élément à comparer

Sélectionnez le deuxième élément à comparer

Sélectionnez le troisième élément à comparer

Laisser un commentaire